时间:2018-06-14 11:02 作者:admin  返回列表

返回列表

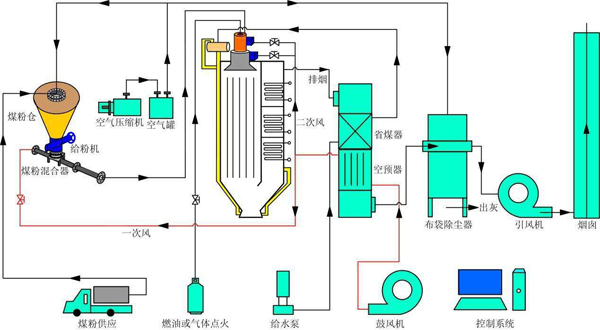

大家都知道低氮燃烧器主要应用于锅炉中,市面上的低氮锅炉成为众多用户的首要选择。那么你知道低氮燃烧器改造后的锅炉与普通锅炉有哪些区别吗?

As we all know, low nitrogen burner is mainly used in boilers, and low nitrogen boiler on the market has become the primary choice for many users. Do you know the difference between the boiler after low nitrogen burner and the ordinary boiler?

1、排放的差异:

由于层燃、室燃、循环流化床锅炉的燃烧方式不同、炉膛结构不同,其原始NOx排放也有较大差异,一般来说,在未特意采用炉内低氮燃烧技术时,循环流化床NOx原始排放低,以链条炉为代表的层燃炉NOx原始排放也略低,煤粉工业锅炉为室燃锅炉,NOx原始排放越高,国内知名的低氮锅炉都排放却大大降低。

1. Differences in emissions:

Because of the different combustion modes and the different furnace structure, the original NOx emission of the layer combustion, the chamber combustion and the circulating fluidized bed boiler is different. Generally speaking, the original emission of the circulating fluidized bed NOx is low when the low nitrogen combustion technology is not specially used in the furnace, and the original emission of the NOx in the layer combustion furnace represented by the chain furnace is also slightly lower. Industrial boilers are chamber fired boilers, and the higher the NOx's original emissions, the less well-known domestic low nitrogen boilers are.

2、锅炉技术不同:

层燃、室燃、循环流化床锅炉可根据燃烧方式的不同采用不同的低氮燃烧技术,针对层燃锅炉配风较常采用空气分级以及烟气再循环来实现低氮燃烧;在烟气再循环对层燃锅炉典型区段燃烧的影响下,结合空气分级技术通过半焦催化还原NOx;炉内超级还原脱硝技术是近年来新兴的炉内脱硝技术手段,通过在燃烧火焰区域的合理位置喷氨,实现在高温火焰中直接脱硝。低氮锅炉主要对二次风口、给煤口的位置及分布进行优化调整,或是增加烟气再循环系统等。

2. The technology of boiler is different:

Different low nitrogen combustion technology can be used in the layer combustion, room combustion and circulating fluidized bed boiler according to the different combustion modes. The low nitrogen combustion is realized by air classification and gas recirculation for the air distribution of the layer combustion boiler. Under the influence of the combustion of the typical section of the layer combustion boiler, the gas recirculation is combined with the air classification technology to pass the semi coke. Catalytic reduction of NOx, the technology of super reduction and denitrification in the furnace is a new technology for denitrification in the furnace in recent years. By spraying ammonia at a reasonable position in the burning flame area, the direct denitrification can be achieved in the high temperature flame. The low nitrogen boiler mainly adjusts and adjusts the location and distribution of the two outlets, coal outlets, or increases the flue gas recirculation system.

3、安全性不同

中心在对层燃、室燃、循环流化床锅炉的炉内低氮燃烧技术进行了大量试验后,已在工程应用上加以验证,总体来说低氮锅炉,安全性要更高一些,之所以近年来它的销量越来越高,有众多用户是因为它的安全性高,对空间环境的威胁小而购买,这也是它与普通锅炉的重要差异之一。

低氮锅炉技术创新产品,是生产节能环保型产品的根本所在,低氮锅炉技术经过多次大量的试验和工程应用上的验证,已经取得了很大的成果,低氮锅炉在很多产业上有了广泛的运用,不仅保护了环境,节能,还控制了污染,这项技术也特别值得我们为之继续进行研究和开发应用。

3. Different security

After a lot of experiments on low nitrogen combustion technology in the furnace of layer combustion, room combustion and circulating fluidized bed boiler, the center has been verified in engineering application. In general, the low nitrogen boiler has a higher safety. In recent years, its sales volume is higher and higher. There are many users because of its high safety and space ring. The threat of the environment is small and the purchase is also one of the important differences between it and ordinary boilers.

The technology innovation product of low nitrogen boiler is the root of the production of energy saving and environmental protection products. The low nitrogen boiler technology has made great achievements in many experiments and engineering applications. The low nitrogen boiler has been widely used in many industries, not only protecting the environment, saving energy, but also controlling the pollution. This technology is also worthy of our continued research and development.

Copyright © 2018 北京众诚永源节能环保技术有限公司 专注于低氮燃烧器设计、改造、销售和安装。网站地图 备案号:京ICP备10001485号-1

北京网站建设:蓝杉互动