时间:2018-06-19 11:51 作者:admin  返回列表

返回列表

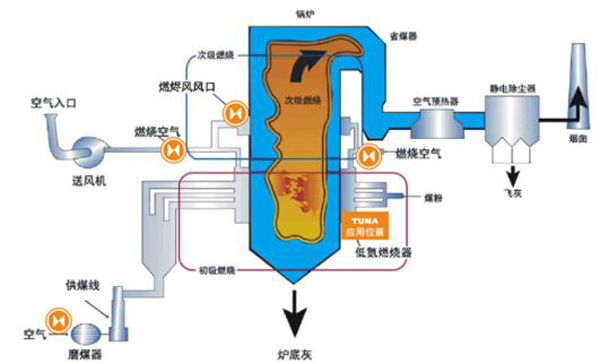

根据《中华人民共和国大气污染防治法》、北京市《锅炉大气污染物排放标准》(DB11/139-2015)的规定,自2017年4月1日起,对燃气锅炉排放浓度超过80毫克/立方米的单位应处10—100万罚款,情节严重的,责令停业、关闭。2017是“清煤降氮”的关键之年,今年越来越多的企业加入到锅炉改造的大潮中,那么锅炉低氮燃烧器改造的注意事项有哪些呢?

According to the law of the People's Republic of China on the prevention and control of atmospheric pollution, Beijing "boiler air pollutant emission standard" (DB11/139-2015), since April 1, 2017, the concentration of gas boiler emissions more than 80 mg/cubic meter of the unit should be about 10, 1 million fine, if the circumstances are serious, shall be ordered to shut, shut down. 2017 is the key year of "clean coal and reduce nitrogen". This year more and more enterprises are joining the trend of boiler reform.

(1)锅炉低氮燃烧器改造注意事项一:调试之前的检查

Note for boiler low nitrogen burner renovation 1: inspection before commissioning

查看低氮燃烧器的燃气是否到位,燃气管路的是否干净通畅,阀门是否已开启。低氮燃烧器有无管路泄露现象,管道安装是否合理。从燃气阀前管道放气排空,以确保管路中无混合空气,同时排空管应接出室外。

Check whether the gas of the low nitrogen burner is in place, whether the gas pipeline is clean and free, and whether the valve has been opened. Low nitrogen burners with or without pipeline leakage, pipeline installation is reasonable. Drain air from the pipe in front of the gas valve to ensure that there is no mixed air in the pipeline and the drain pipe should be outside.

(2)锅炉低氮燃烧器改造注意事项二:燃烧稳定和燃烧的动态平衡

Attention to the reform of boiler low nitrogen burner two: combustion stability and dynamic balance

切记燃烧调整是低氮燃烧器一切调整的基础,对于汽温来说燃烧更是本质,不论在任何工况变化下只要保证燃烧稳定和燃烧的动态平衡,因为汽温是烟气发热量与蒸汽吸热量相平衡的标志,只要能维持这个动态平衡,汽温就能保持稳定。

Remember that combustion adjustment is the basis of all low nitrogen burner adjustment, combustion is essential for steam temperature, under any condition change, no matter as long as the guarantee stability and combustion of dynamic balance, because the steam temperature is a sign of flue gas heat and steam heat absorption phase equilibrium, as long as you can to maintain the dynamic balance, steam temperature can remain stable.

(3)锅炉低氮燃烧器改造注意事项三:锅炉的火焰中心

Note for boiler low nitrogen burner renovation 3: boiler flame center

锅炉火焰中心的高低也是影响汽温高低的重要因素,在运行中汽温高时可减小上排燃烧器煤量增加下排燃烧器煤量,反之亦然。低氮燃烧器在运行中还要注意磨煤机不同组合方式运行对汽温的影响,下排组合烟温水平低汽温调节裕度大,而上排组合烟温水平高造成汽温调节裕度小易超温,要根据情况及时加强吹灰和注意调整配风。

The height of the boiler flame center is also an important factor influencing the temperature of steam. When the temperature of steam is high, the amount of coal in the upper exhauster can be reduced and the amount of coal in the lower burner can be increased, and vice versa. Also note in the operation of the low nitrogen burner in coal mill run different combinations of the influence of steam temperature, discharge low level of combined smoke temperature steam temperature regulation margin, and combination on the smoke temperature caused high steam temperature regulating margin small yi chao wen, according to the situation in a timely manner to strengthen blowing and pay attention to adjust the air distribution.

由于锅炉低氮燃烧器在市场上运营改造的时间短,对问题的认识还不充分,对处理问题的经验还不足,为缓解燃煤发电厂的环保压力,降低氮的减排技术还需进一步研究和发展,选择值得相信的低氮燃烧器尤其重要。更为重要的是在新的减排技术和环保设施应用后产生的问题处理能力要进一步提升,为燃煤发电厂的可持续发展争取更大的环保效益。

Nitrogen burner on the market because of the low boiler operating time is short of, understanding of the problem is not enough, but not enough experience to deal with problems, coal-fired power plants to alleviate environmental pressure, reduce nitrogen emissions technology still need further research and development, choose low nitrogen burner that is worth of trust is particularly important. More importantly, after the application of new emission reduction technologies and environmental protection facilities, the capacity to deal with problems will be further improved, so as to achieve greater environmental benefits for the sustainable development of coal-fired power plants.

Copyright © 2018 北京众诚永源节能环保技术有限公司 专注于低氮燃烧器设计、改造、销售和安装。网站地图 备案号:京ICP备10001485号-1

北京网站建设:蓝杉互动